Our fine industrial glass beads are high-quality soda-lime blasting media for precision metal finishing, shot peening, and surface preparation. Available in 50 lb boxes or full pallet bulk shipments, this MIL-PRF-9954D & AMS-certified glass bead media is perfect for manufacturers, metal fabricators, and hobbyists alike. Whether you need small retail quantities or wholesale orders, we ship nationwide.

Why Use Fine Glass Beads for Blasting?

Glass bead blasting will NOT damage your substrate, penetrate, contaminate, leave residue, or make dimensional changes to your base material. It will leave an even, spherical impression anchor profile. Works very well on softer metals such as brass, aluminum, plastic, die-cast surfaces. (Try plastic beads if you need something even more gentle.) Glass bead cleaning removes residue and oxide layers, allowing future plating or painting coatings to adhere better. Wet blasting can expose cracks in metals that might otherwise go unnoticed (cracks will appear as a fine dark line.) Bead cleaning can restore lost performance of parts due to buildup of heat scale and carbon deposits. Surface treatment and finishing with glass beads can improve sealing, appearance, can blend surface defects on all types of dies, molds, and complicated shapes while improving corrosion resistance and moving part lubrication.

Deburring with glass beads will remove loose burrs, edges and nicks. Example applications would include deburring castings, gears, dies, jigs, tools, machine parts. Peening with glass beads is especially effective with parts like springs, crank shafts, and gears, which have flexional demands.

Glass bead blast abrasives media comes in different sizes just like other abrasives do, but they generally use a different sizing chart, please see the chart below. The main purpose for shot blasting with glass bead media is to create a compressive stress pattern and the elimination of microscopic defects in the surface of your part. However, there are hundreds, if not thousands of different applications using glass beads.

Glass beads contain NO FREE SILICA. Glass bead blasting will not leach toxins into the environment, will not leave residue on work pieces, will not cause dimensional changes to the base part being cleaned. Bead blasting will leave even and spherical impressions on the pieces being cleaned, and will create and anchor profile for new paint to adhere to. These glass beads are suitable for suction (80 psi max. pressure), pressure pot (40 psi max. pressure), as well as wet and dry blasting operations. They are made from hardened soda lime glass, and is available in all standard sizes, and have a low breakdown rate, lower disposal, and lower maintenance costs vs other cleaning methods such as harsh and chemical treatments.

Packaging: 50 lb bags on a pallet, 40/pallet = one net ton (2000 lbs) per pallet is standard packaging. ** Minimum order is 100 lbs, or two boxes.

💼 Request a Wholesale Quote

Sizes & Specifications

Available in either MIL-PRF-9954D, or AMS (Aerospace Material Spec). We will ship MIL SPEC, NON-AMS media unless you specify this by selecting the appropriate variant.

#1 through #13 mil spec MIL-PRF-9954D, or AMS spec are available. The AMS Spec beads are a slightly tighter size range than mil spec, and have more round beads, yet are the same chemical composition of glass beads. (Note: The minimum % of rounded beads will differ from size to size: 65% to 90% depending on size of bead). This is why AMS is slightly more expensive. An AMS spec bead is generally used for shot peening and a Mil spec bead is generally used for shot blasting. COA's are available for either Mil Spec, or AMS, but not both (simply because they are different stock numbers). To be clear, all AMS beads will meet both Mil Spec (a lower quality, larger distribution bead) as well as the Aerospace Material Spec. IF YOU ORDER MIL SPEC MEDIA WE CANNOT SEND IT WITH AMS CERTIFICATION AND VICE VERSA. WHAT YOU ORDER HAS TO MATCH THE CORRESPONDING SPECIFICATION.

Current Mil Spec Certs will be PRF-9954D. The letter "D" is indicative of the revision (meaning that 9954B is older than 9954D). The newest version of the Specs supersedes all older versions. (For example. Glass Bead Mil-G-9954A: This spec has been superseded by MIL-PRF-9954B, and 9954B has now been superseded by 9954D) MIL-PRF = Military Performance Specifications

Please see the AGB TO MIL SPEC CONVERSION CHART by scrolling down.

Additional Specs: Our glass bead will meet SAE AMS 2340S (This specification covers the requirements for automatic shot peening of surfaces of parts by impingement of media, including metallic, glass, or ceramic shot) as well as AMS2431/6C (This specification, in conjunction with the general requirements covered in AMS 2431 establishes the requirements for glass shot to be used for peening of metal parts).

- Knoop Hardness: 515

- Mohs Hardness: 5.5

- Packaged in 50lb bags

- Color: Clear or colorless

- Lead Free? YES! Our beads are lead free

- Density: 2.5 g/cc

- Bulk Weight: 1.5 kg/ltr

- Soda Lime Glass: No free silica

- Specific Gravity: 2.45-2.50 g/cm3

- Toxicity: None

- Shape: Spherical, 65-95% as required

Common Applications:

- Surface Etching

- Aluminum Casting

- Medical Equipment

- Stainless Steel Parts

- Food Processing Equipment

- Shot Peening

- To Create a Uniform Appearance

- To Remove Marks and Scuffs on Surface of part

- Surface Prep prior to coating

- Peening in order to increase the strength of the part

- Burr Removal

| Application | Benefit |

|---|---|

| Aluminum casting cleaning | Removes oxidation, preps for coating |

| Stainless steel finishing | Improves corrosion resistance |

| Shot peening springs/gears | Increases fatigue strength |

| Food processing equipment | Non-toxic, lead-free, residue-free |

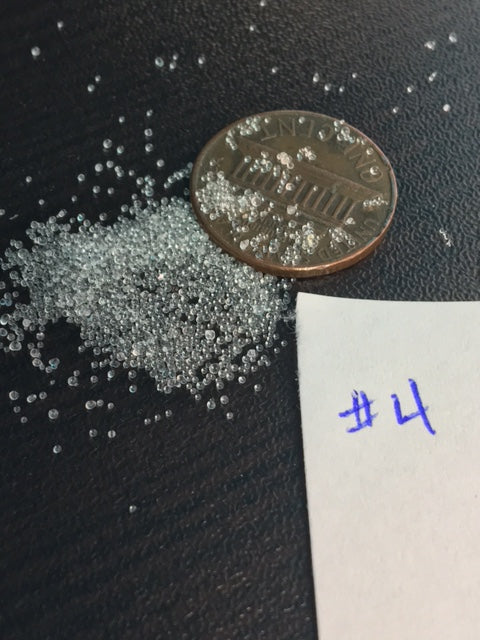

Making Weighted Blankets or Reborn Life Like Dolls? Try bead sizes 1-4! Some customers will also use the larger grinding & milling beads. It all depends on your fabric and your stitching.

Shuffleboard Games - Order AMS/AGB100 as these beads have a tighter distribution, more fully rounded beads, and are excellent for shuffleboard surfaces

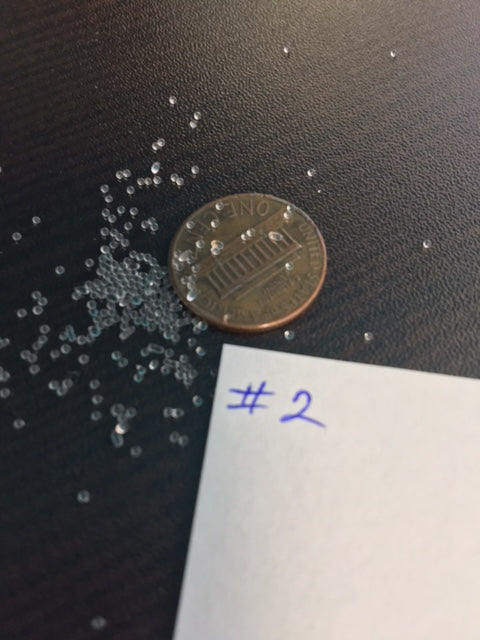

Shuffleboard Surface: A variety of bead sizes can be used, depending on how smooth your surface is. If very smooth, try a #4 bead. If not so smooth, try a #2 (larger) bead. We can send you some viewing samples if you like.

💼 Request a Wholesale Quote

__________

Mil Spec Sizing Generalities:

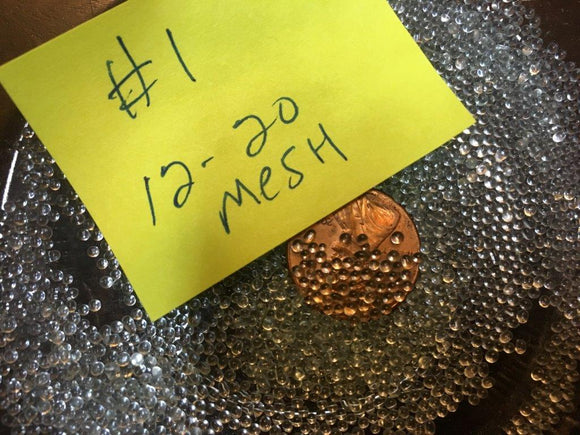

- 1 is a 12-20 sieve (0.85-1.70 mm), #2 is a 14-30 sieve

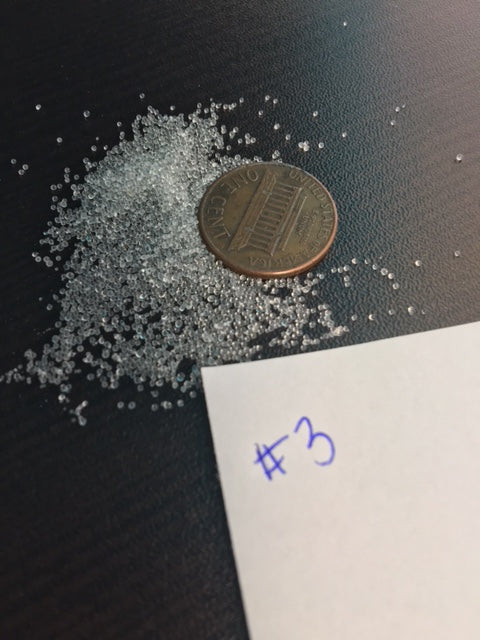

- 3 is very coarse, see chart below

- 6 is medium to coarse

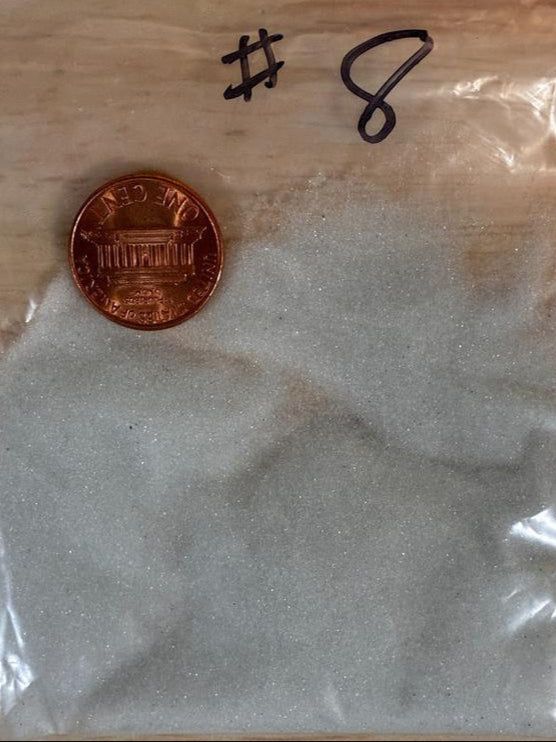

- 8 is considered a medium and is the most commonly used size

- 10 is a medium to fine

- 13 is very fine

| MIL-PRF-9954D | ||||||

| Size | US Sieve | Inches Max | Inches Min | Microns Max | Microns Min | Min % Round |

| 3 | 20-30 | .0331 | .0234 | 850 | 600 | 65 |

| 4 | 30-40 | .0234 | .0165 | 600 | 425 | 70 |

| 5 | 40-50 | .0165 | .0117 | 425 | 300 | 70 |

| 6 | 50-70 | .0117 | .0083 | 300 | 212 | 80 |

| 7 | 60-80 | .0098 | .0070 | 250 | 180 | 80 |

| 8 | 70-100 | .0083 | .0059 | 212 | 150 | 80 |

| 9 | 80-120 | .0070 | .0049 | 180 | 125 | 80 |

| 10 | 100-170 | .0059 | .0035 | 150 | 90 | 90 |

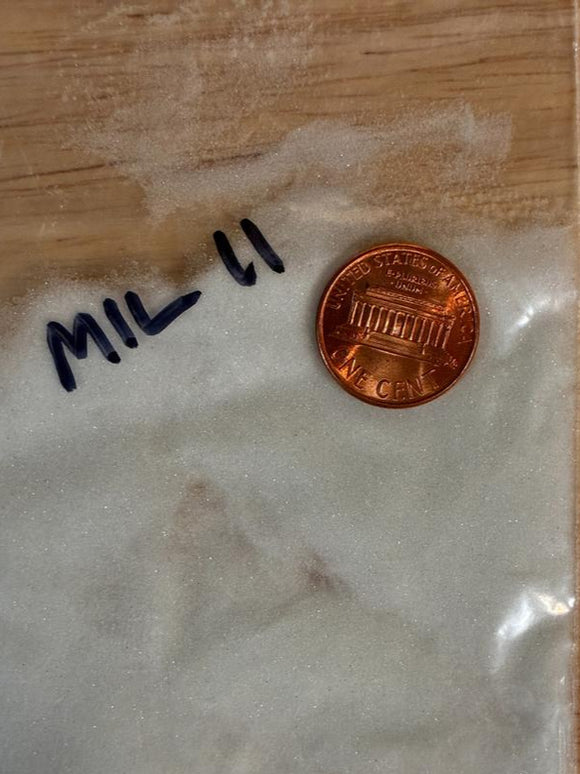

| 11 | 120-200 | .0049 | .0029 | 125 | 75 | 90 |

| 12 | 140-230 | .0041 | .0025 | 106 | 63 | 90 |

| 13 | 170-325 | .0035 | .0017 | 90 | 45 | 95 |

AGB TO MIL SPEC CONVERSION CHART:

AGB-150 – MIL-1

AGB-100 – MIL-2

AGB-70 – MIL-3

AGB-50 – MIL-4

AGB-35 – MIL-5

AGB-25 – MIL-6

AGB-20 – MIL-7

AGB-18 – MIL-8

AGB-15 – MIL-9

AGB-12 – MIL-10

AGB-10 – MIL-11

AGB-9 – MIL-12

AGB-6 – MIL-13