Versatile High-Performance Abrasive for Demanding Applications

Harness the exceptional cutting power of our premium Black Silicon Carbide (SiC) abrasive grit. Known for its sharp, angular particles and superior friability, this industrial-grade abrasive delivers consistent results across a wide range of applications.

Key Benefits:

- Superior Hardness (9.1 Mohs) - Cuts through tough materials with exceptional efficiency

- Sharp, Angular Particles - Aggressive cutting action for faster material removal

- Self-Sharpening Properties - Maintains cutting efficiency throughout use

- Excellent Friability - Fractures to expose fresh cutting edges

- Chemical Resistance - Stable performance in various environments

- Cost-Effective Performance - Lower consumption rates reduce operating costs

Ideal Applications:

- Surface preparation and cleaning of metals, ceramics, and composites

- Grinding wheels, Discs for tool and die manufacturing

- Anti-skid, traction, concrete and flooring broadcast abrasive media

- Lapidary rock and stone tumbling

- Lapping and polishing of hard materials

- Refractory and ceramic production

- Non-slip surface treatments

- Glass Etching & Frosting: Architectural glass, decorative panels, signage applications

Complete Grade Selection:

Choose from our full range of ANSI/FEPA standard grades from coarse to ultra-fine. Each grade is precisely sized and classified for consistent particle distribution and optimal performance in your specific application.

Why Choose Our Black Silicon Carbide?

Imagine achieving superior surface finishes while reducing processing time and abrasive consumption. Our high-purity SiC delivers the aggressive cutting action and durability you need for the most demanding industrial applications.

Minimum order: 50 lbs per grade, boxed

Quality: Consistent sizing and purity for reliable, repeatable results. ANSI & FEPA

Additional Information: Black silicon carbide is generally used for the abrasive wheel, slurry, refractory and ceramic industries. SiC is special in the way it breaks down. As it breaks down the media will fracture, exposing new, sharp edges. It is therefore the number one abrasive to use in rock tumbling. Simply keep adding new coarser grit, and as the media breaks down, it will create a "working blend" of various sized particles. This allows for effective surface cleaning/polishing.

SiC is harder than aluminum oxide, and a bit more friable than brown fused AO. Carborundum is very hard. The only two common abrasive materials harder than SiC are diamond and boron carbide. Due to its much lower cost than diamond or B4C, it is widely used for grinding nonferrous materials, finishing tough and hard materials, as well as filling up ceramic parts. It is therefore perfect for rock tumbling, sandpaper, sandblasting, vitrified and resinoid grinding wheels, lapping, compounds, non-slip (anti-skid), wire-sawing silicon & quartz, polishing, and tumbling.

Minimum order for black silicon carbide is a 25lb box, online ordering. If you only need 25lbs, use this page to order. Repackaging/Processing lead times are usually ~3 business days, but will ship sooner if possible.

Standard packaging is a 300lb drum or 2000 lb supersacks. Please use our Quote Request Form for Wholesale Price Inquiries.

SPECIAL NOTE ON 49 LB BOXES!!! Due to UPS charging huge fees for boxes weighing over 50 lbs, we are forced to short each box a pound or two. This is why we are now calling our 50lb boxes "49 lb boxes". This is the best solution we could come up with in order to get you the cheapest shipping rate possible. If you only need 25lbs, use this page to order. We highly suggest buying buckets at a hardware store and repacking into buckets in order to seal out humidity and moisture. The cost to ship pails far exceeds the cost of a bucket - UPS charges high fees for every pail they have to manually process.

Common Applications for Black Silicon Carbide Grit & Powders:

- Ceramic, metal lapping, and polishing applications

- Abrasive Flow Machining

- SiC Sandpaper, grinding wheels, cut off tools

- Slicing of silicon carbide wafers

- Rock and stone polishing and engraving

- Extrude Honing, Cleaning (such as cleaning gas turbine engine ports)

- AFM: Abrasive Flow Machining (finishing technologies, fine flow tuning surfaces, edge blending)

- Slicing, lapping, polishing glass and germanium wafers

- Die Extrusion

- Bottle Glass Etching, Glass Carving, Glass Polshing

- Lapping of piston rings and gears

- Grinding of nonferrous materials

- Finishing tough and hard materials

- Bonded abrasive tool applications

- Glass etching and glass carving industries

- Rock tumbling industries - Lapidary use, vibratory machines

- Making concrete "sparkle" in the sunshine

- Aggressive Concrete Anti Slip: Broadcast 8, 12, 14, 16 grits single or mixed sizes onto concrete. For example, 8 and 12 grits are great for meat packing and dairy floors.

- Concrete additive: anti-slip grit to broadcast on concrete flooring, sidewalks, plazas, driveways. The 16/36 blend is perfect as a non slip broadcasting media. (**NOT recommended around children's play areas or swimming pools as it will cause abrasion-type injuries when (not if) children fall down). You may also use it to make concrete sparkle, applied at 1/4 lb. / square foot). For more anti slip feature, use a straight 16 grit rather than the blend of 16/36.

Specifications of Silicon Carbide:

- Thermal Conductivity: High (100 W/m-K) approximately.

- High strength at elevated temperatures (at 1000°C, SiC is 7.5 times stronger than Al2O3).

- Black Silicon Carbide contains some free silicon (Si) and carbon (C) and is not as pure as Green SiC.

- Incompatibilities: None

- Gradation: Coarse grades meet both ANSI & FEPA; 220 and Finer grades are FEPA Graded, "P" shaped particles are also available. The entire ANSI and FEPA gradations are available. "P" shaped media cannot be ordered online, you will need to call or email us for pricing.

- Macro Grit Sizes: 8 grit - 240 grit (ANSI); P12 - P220 (FEPA). Micro Grit Sizes: F280 grit - F1200 grit (FEPA); P240 - P3000 (FEPA)

- Typical Packaging: 300lb Drums, 50lb bags, 25lb boxes

- Odor: Odorless

- Safety: Avoid breathing dust; wear protective gear

- Purity: 99% approximate

- Friability: Semi-Friable

- Pricing Based Per: Pound

- Structure: Monocrystalline

- NMF Classification: Class 55

- Fire & Explosion: Fines can cause explosion and smolder

- Keep away from all sources of ignition

- Color: Black

- Hardness: Knoop 2480 - 2550 / Mohs 9.1

- Instability: Stable

- Hazardous? Not listed as hazardous; see other cautions

- Disposal: According to Federal, State, Local regulations

- Grain Shape: Blocky, sharp edged OR we can also sell you "P" material, which is angular, with sharp edges. "P" shaped media cannot be ordered online, you will need to call or email us for pricing.

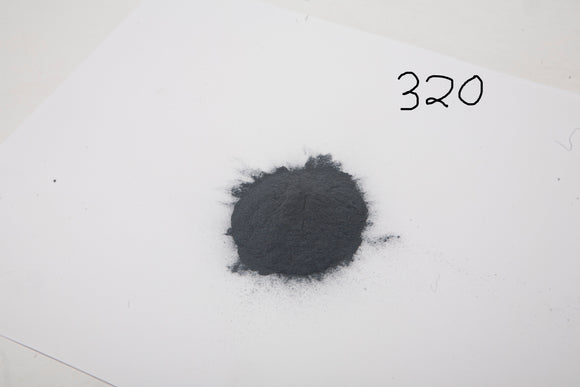

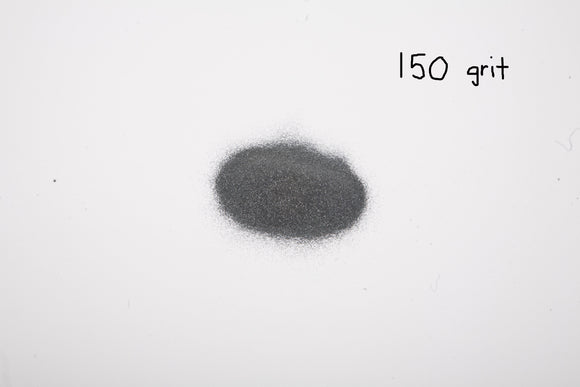

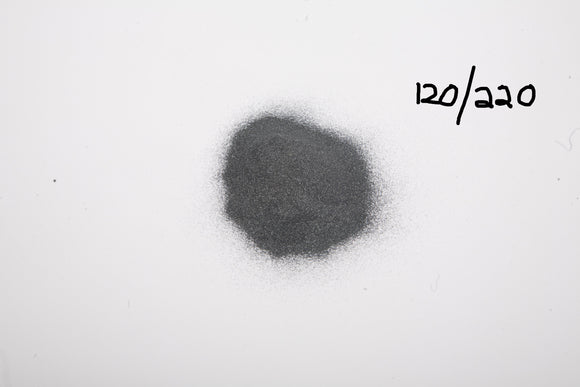

- Type: Granular or powdery depending on grade

- Specific Gravity: 3.2 (SiC)

- Bulk Density: ANSI B74.12-1988 normal bulk Density range is 1.45 - 1.55 (If you need a high density media, ask us. We can see if we have a lot number that meets your criteria.

- Manmade from silica sand and carbon

- Oxidation: SIC will not oxidize until it reaches a temperature of ~1200C. If it was placed in a harsh environment, such as an acid fog then it might oxidize earlier. You might see a slight color change when the material is wet vs dry.

Sizes Available:

- Macro Grit Sizes: 8 grit - 240 grit (ANSI); P12 - P220 (FEPA).

- Micro Grit Sizes: F280 grit - F1200 grit (FEPA); P240 - P3000 (FEPA)

- JIS Sizes upon request are available in finer sizes only.

- Split Sizes: 16/36 (anti skid broadcasting blend. To make concrete sparkle, we suggest our 16/36 blend, applied at 1/4 lb. / square foot), 30/60 (often used in making saw blades), 46/70 (rock tumbling), 54/70 (rock tumbling), 60/90 (rock tumbling), 100/120, 120/220 (rock tumbling), 150/220 (rock tumbling), 180/240, 500/600 (rock tumbling). Split sizes include all grits in the middle as well. For example, a 120/220 means that it includes 120, 150, 180, and 220 sizes in the blend.