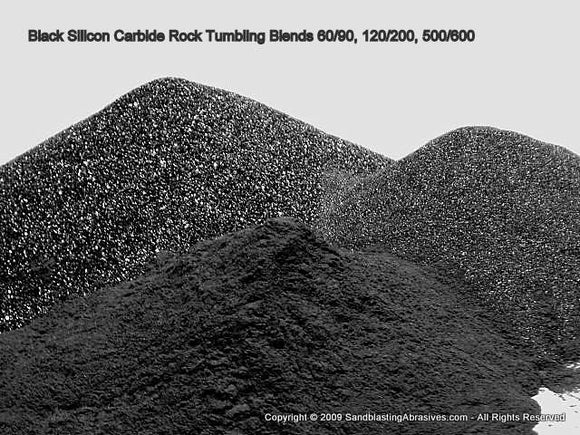

Industrial Black Silicon Carbide Abrasive Media

Industry-leading black silicon carbide (SiC) abrasive media engineered for demanding professional applications across manufacturing, surface preparation, coatings, and precision finishing operations.

Primary Industrial Applications

- High-Tech Coatings: Surface preparation for aerospace, automotive, and marine protective coatings

- Anti-Slip Flooring Systems: Aggregate additive for industrial flooring, walkways, and safety surfaces

- Advanced Ceramics Manufacturing: Precision grinding and finishing of technical ceramics, refractory materials

- Precision Lapping & Polishing: Optical components, semiconductor wafers, precision tooling

- Glass Etching & Frosting: Architectural glass, decorative panels, signage applications

- Metal Finishing: Deburring, surface texturing, and preparation for plating operations

Specialized Professional Markets

- Semiconductor Industry: Wafer lapping, CMP slurries, substrate preparation

- Optical Manufacturing: Lens grinding, mirror polishing, precision optics finishing

- Aerospace Components: Turbine blade finishing, composite surface preparation

- Automotive Manufacturing: Engine component lapping, transmission part finishing

- Medical Device Production: Implant surface texturing, surgical instrument finishing

- Electronics Manufacturing: PCB surface preparation, connector finishing

- Refractory Industry: Kiln furniture grinding, furnace component preparation

- Tool & Die Manufacturing: Precision tooling, mold surface preparation

- Glass Etching & Frosting: Architectural glass, decorative panels, signage applications

- Flooring Applications: Anti slip, traction additive, concrete broadcast abrasive

Technical Specifications

- Material Composition: 99.5% pure black silicon carbide (SiC)

- Crystal Structure: Alpha silicon carbide (α-SiC)

- Hardness: 9.5 Mohs scale (2480 Knoop)

- Density: 3.22 g/cm³

- Melting Point: 2700°C (4892°F)

- Thermal Conductivity: 120 W/m·K

- Chemical Resistance: Excellent acid/alkali resistance

- Particle Shape: Sharp, angular crystals for aggressive cutting action

Quality Standards & Certifications

- FEPA Standards: Compliant with European abrasive grain standards

- ANSI Standards: Meets American National Standards Institute specifications

- ISO 9001: Quality management system certified

- Consistent Sizing: Precision graded for uniform performance

- Low Impurities: Minimal free silicon and metallic contamination

Processing Advantages

- Superior Cutting Efficiency: 40% faster material removal than aluminum oxide

- Consistent Performance: Maintains sharp cutting edges throughout use

- Thermal Stability: Excellent performance at elevated temperatures

- Chemical Inertness: Compatible with most processing fluids and environments

- Recyclable: Can be reclaimed and reused in many applications

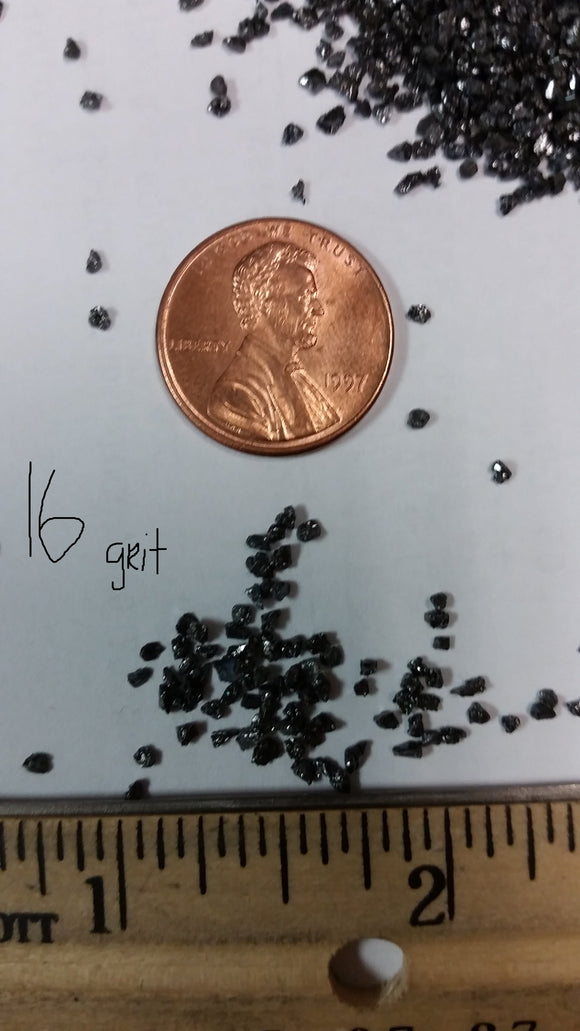

Available Grit Sizes

Coarse Grits (8-36): Heavy stock removal, rough grinding, surface preparation, traction

Medium Grits (46-120): Intermediate finishing, deburring, texture development

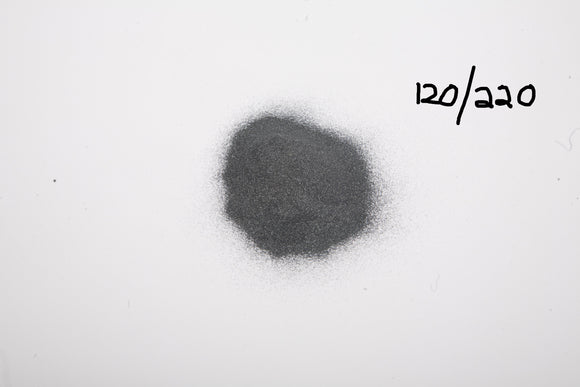

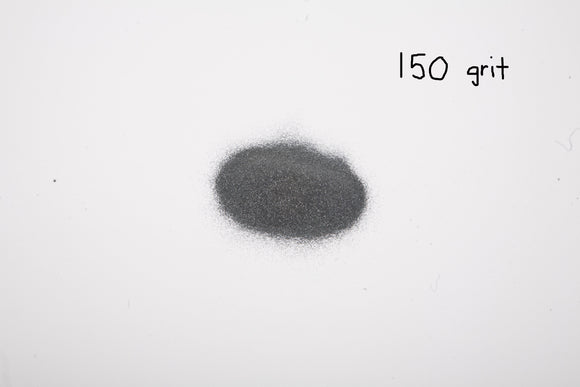

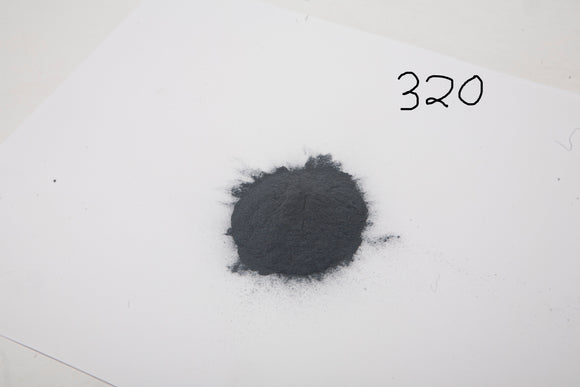

Fine Grits (150-400): Precision lapping, etching, pre-polish operations

Micro Grits (500-1200): Final polishing, optical finishing, ultra-smooth surfaces

Bulk Packaging: 50 lb bags 40/pallet, 300 lb drums 4/pallet, 2,000 lb super sacks

- Residential Delivery? Yes, we can ship to residential address, or a local terminal near you to save residential freight fees.